Custom monolayer extruded film meets innovative optical technology

So what makes Bixby's diffusion film unique?

- Improved beam management for better light diffusion

- Monolayer film is extrusion embossed for more efficient production rates

- UGR (Unified Glare Rating) exceeds current industry requirements

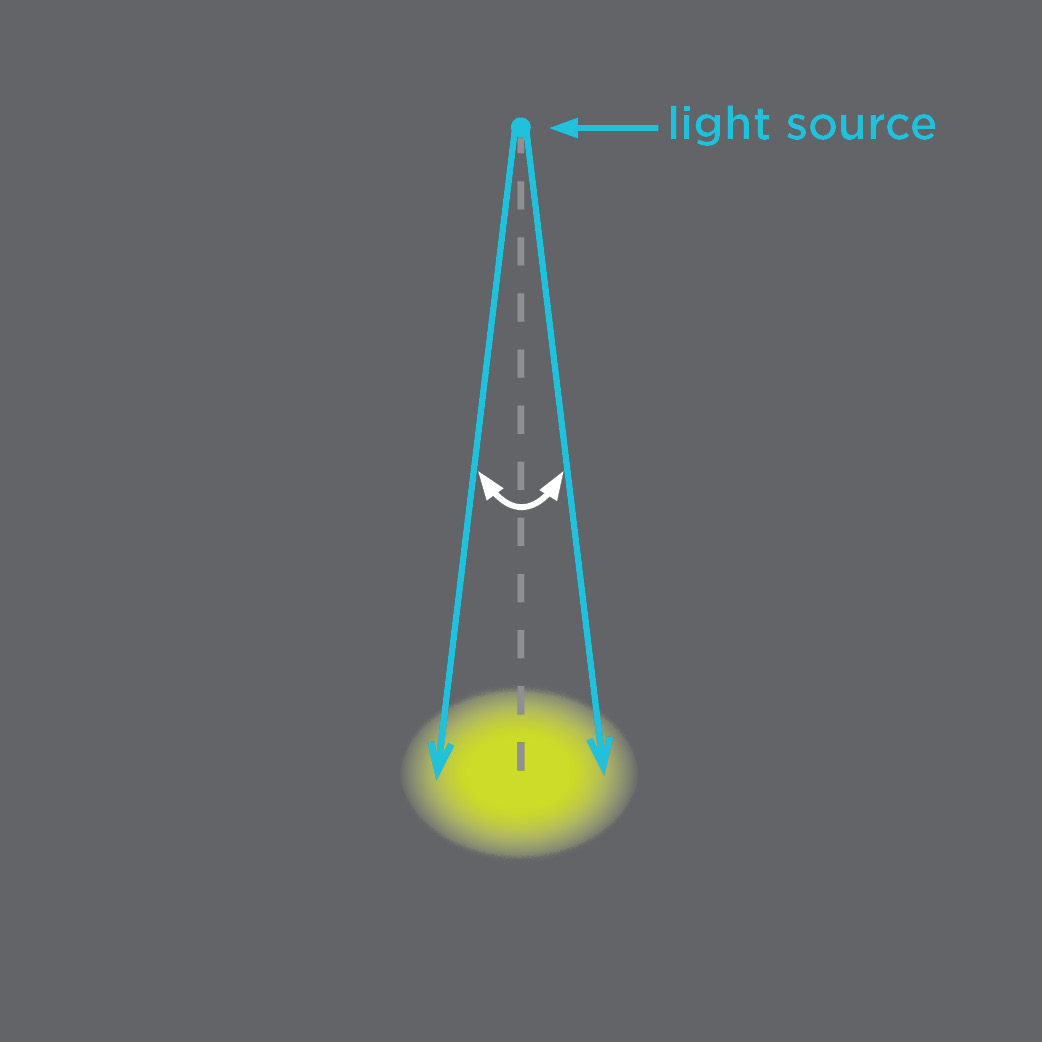

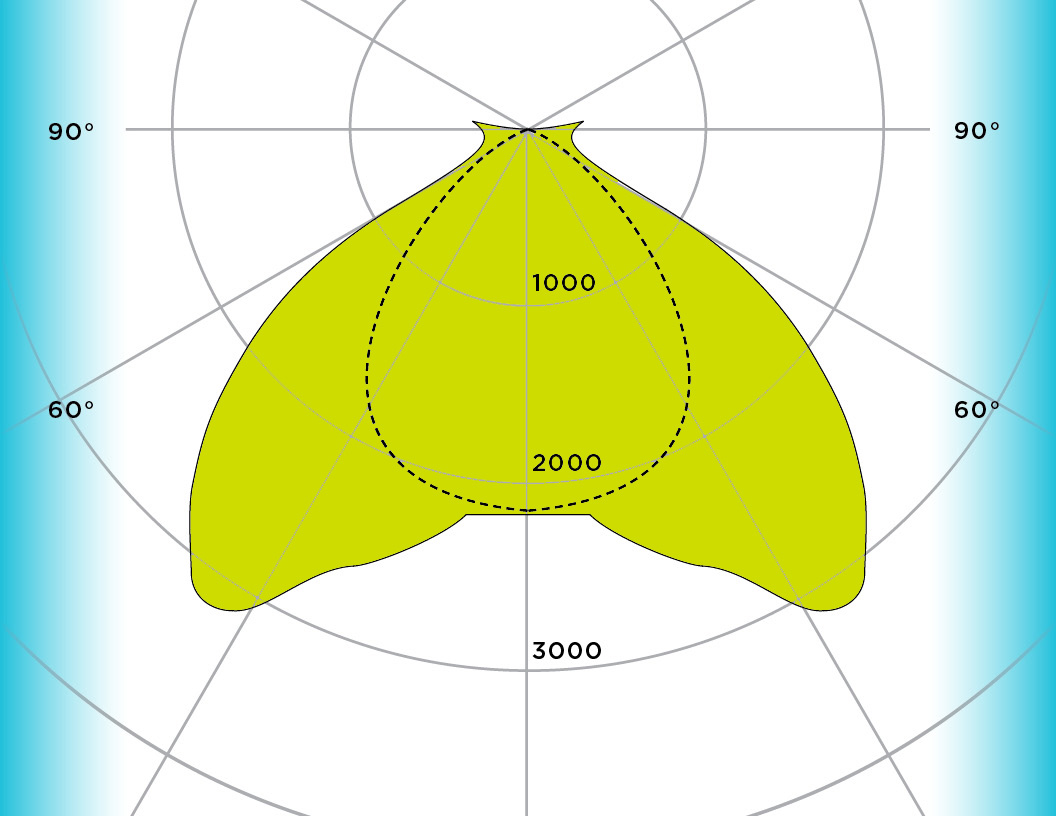

- Technology allows for specific angular control based on architectural or lighting needs

- Highly customizable

- Potential for lower production costs and shorter timelines compared to other manufacturing methods

- No fillers are used to create the hiding effect offering more efficient energy use and light output

- High-hiding film can be mounted closer to the LED source without hotspots or showing LED source

- Patented technology

How do we do it?

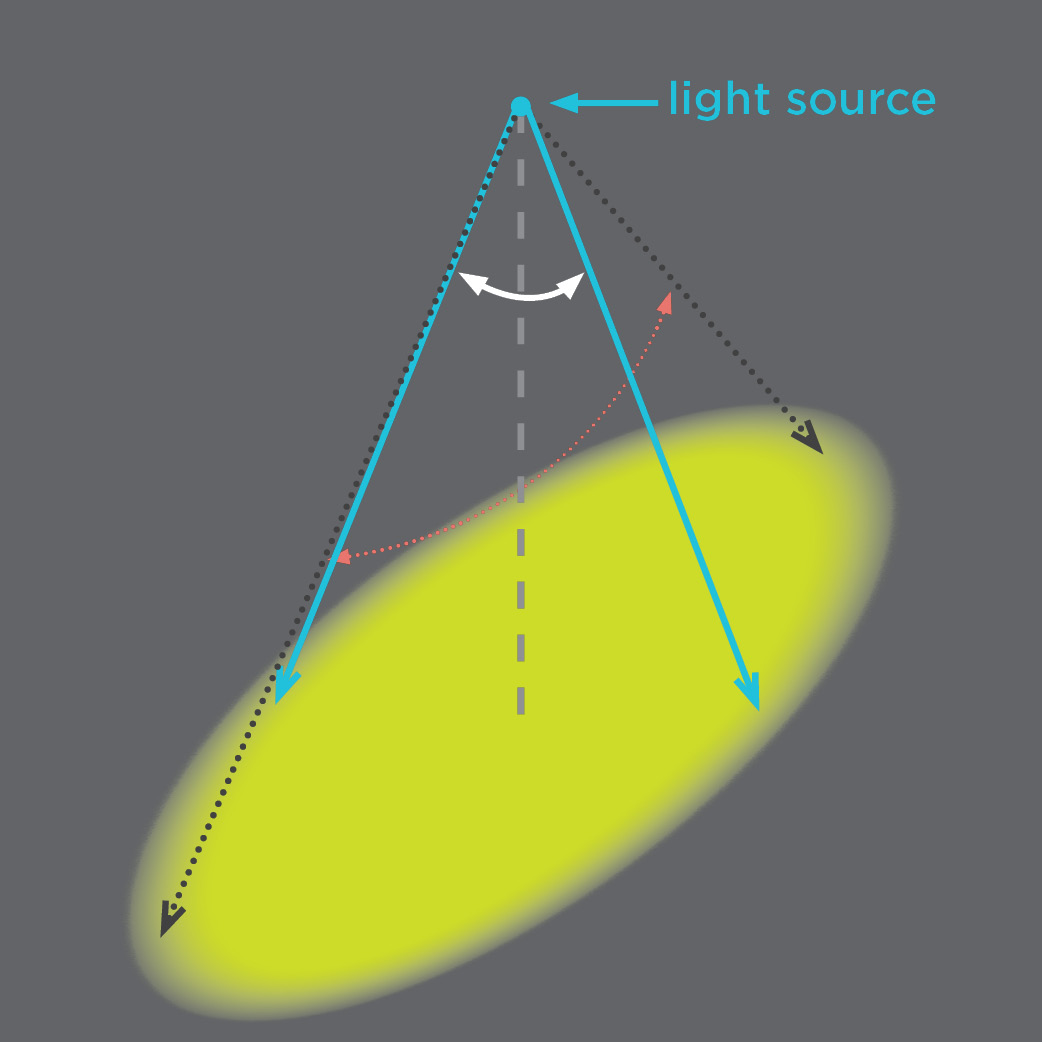

The technology behind Bixby's diffusion film is based on creating a mirror facet array with specific refractive angular control. Every individual facet is designed and oriented to allow the light to pass through and fill the proportional area of our customer's desired output. The orientation of these individual facets is randomized through a patented technology to create sharp images and avoid diffraction effects from its structure. The randomization of the facets prevents visible patterns within the diffuser. This unique, patented technology allows us to manufacture customized films in a more time-efficient process removing the need for multiple production passes, transportation costs, and extensive design trial and error. In fact, custom patterns can be programmed and designed within hours which significantly shortens the tooling process.

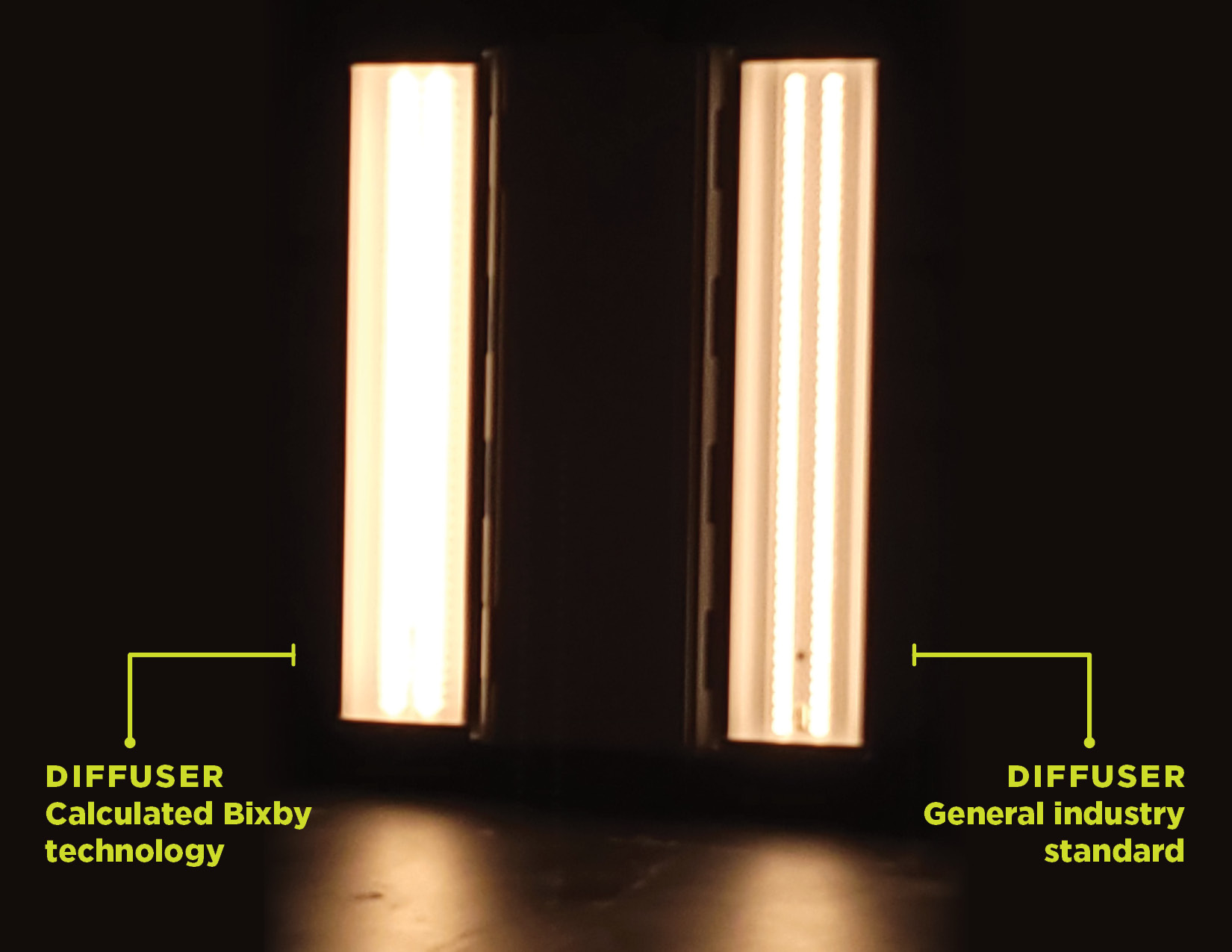

See the difference!

Bixby's calculated diffuser technology is high-hiding without a need for added fillers.

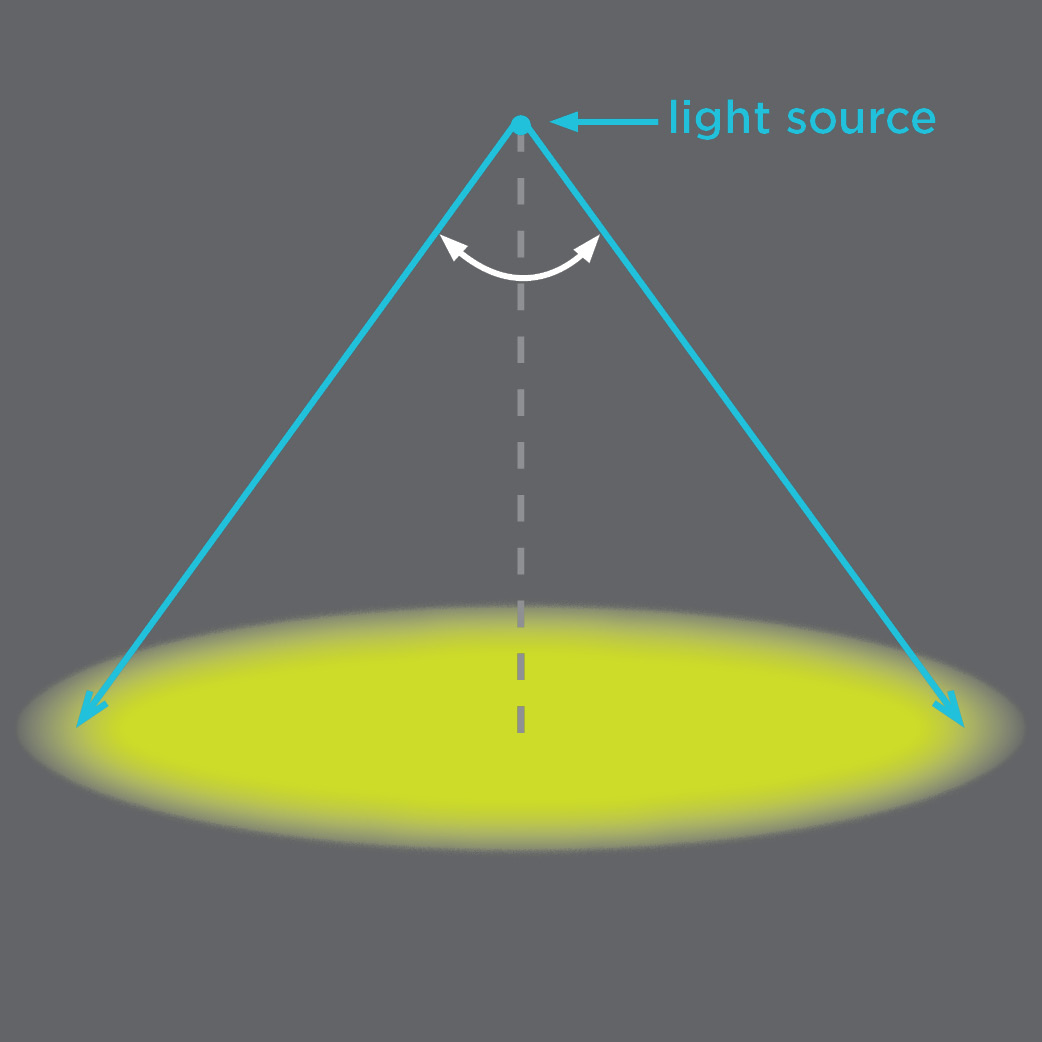

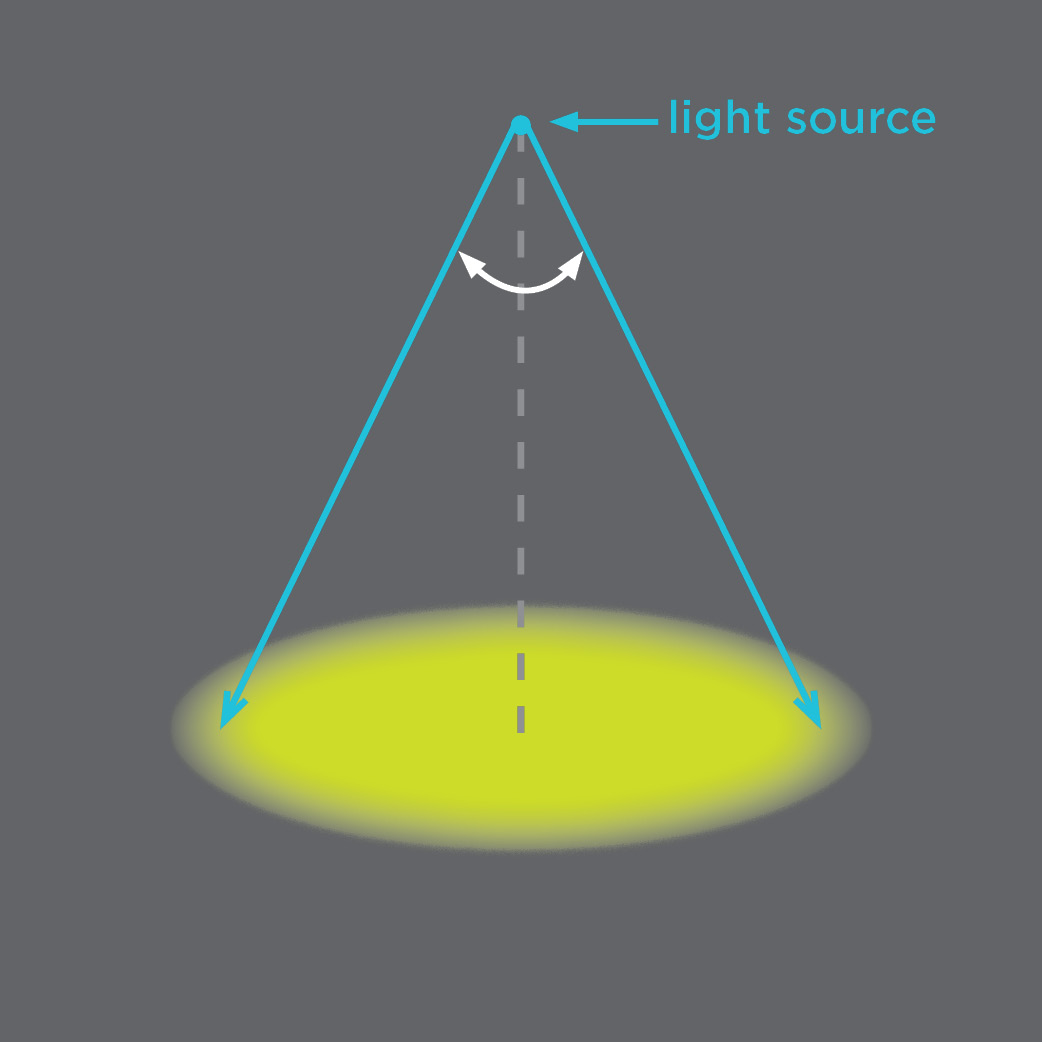

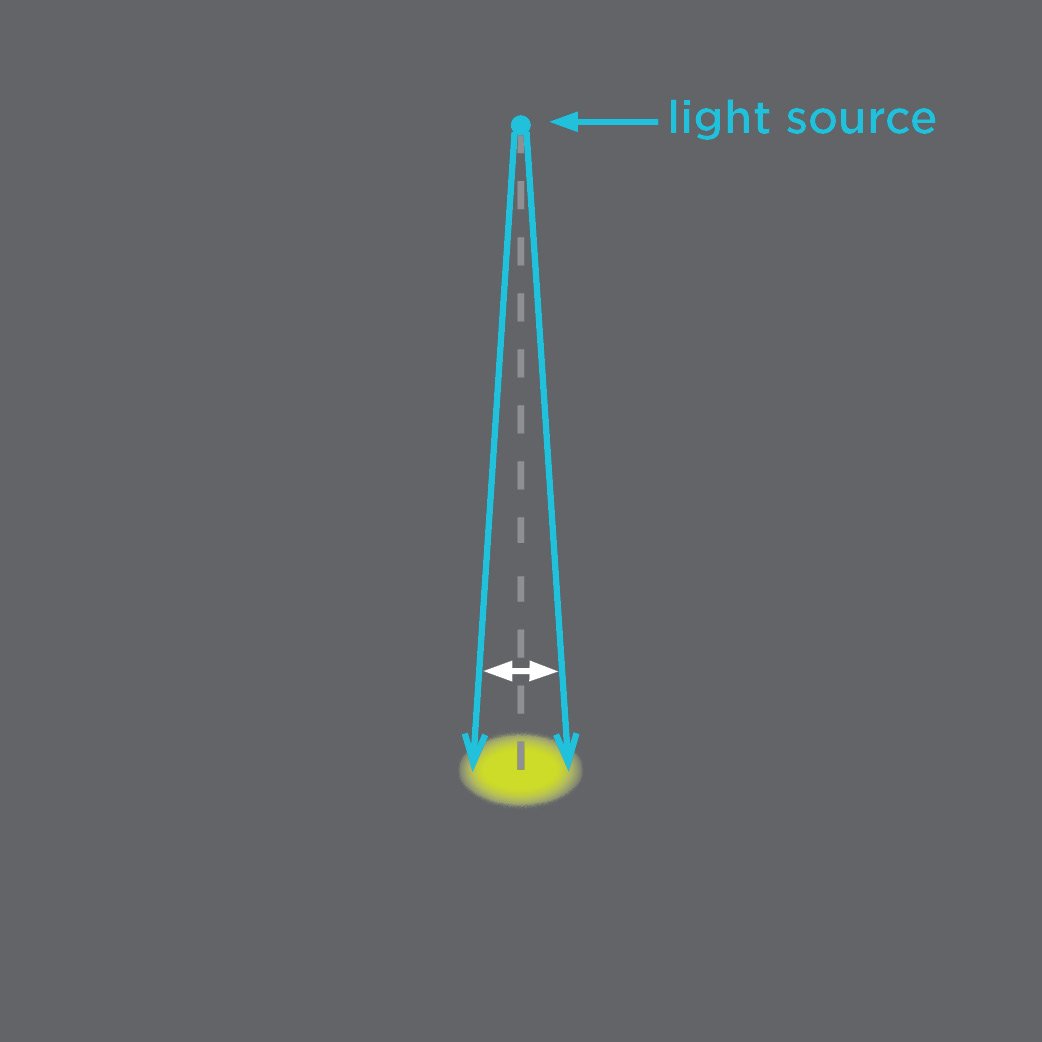

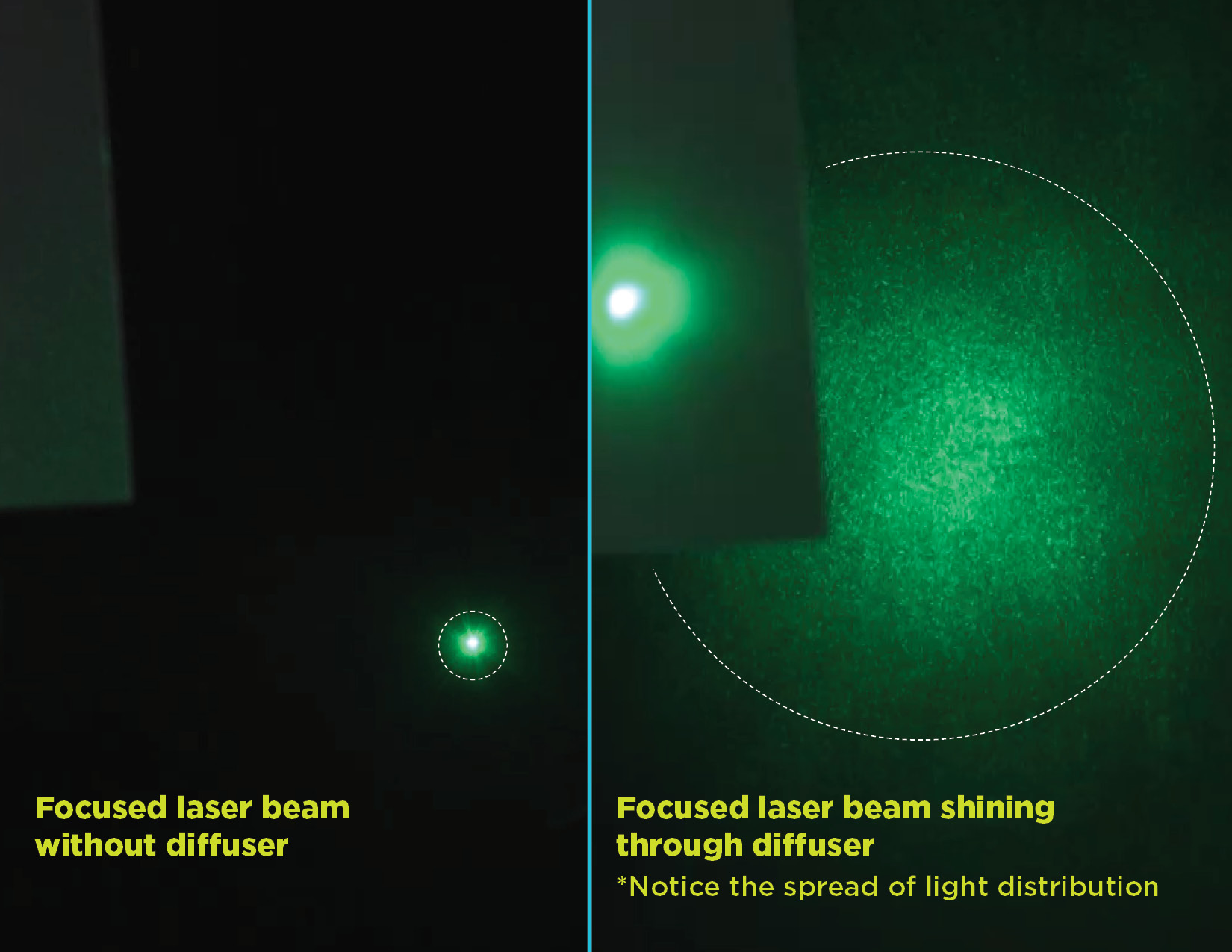

How diffusion works: The output of lighting from the diffused laser covers over 8x the area in comparison to the focused beam without a diffuser. The fractals within the diffusion film increase the lit area based on preferred angles and distribution levels.

Thin films for use as optical displays

CONTACT US

to learn more

about optical

display projects

Specialty coated fabrics and reinforced sheet

Bixby has been supplying high-end specialty sheet products to the specialty coated fabric and reinforced sheet market for over 30 years. Our unique processing capabilities and ability to produce a diverse range of specialty plastic resins allows us to provide a diverse portfolio of products to the specialty coated fabric and reinforced sheet market.

Bixby provides both single-layer and multi-layer sheets, including sheets integrated with reinforcing scrims and woven and non-woven fabrics. Our high-end process allows us to produce sheets of the highest quality that are used to make a wide variety of coated fabrics and reinforced sheets.