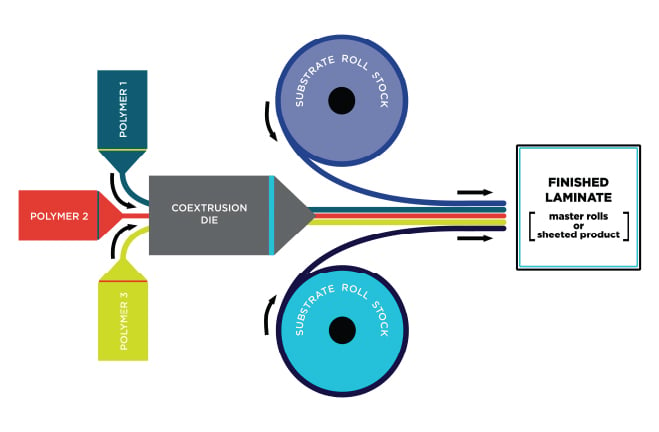

The COEXTRUSION process allows compatible thermoplastic materials to be fed from multiple extruders into the same feed block and multilayer die assembly. This allows polymers to interact improving the bond strength between plastic layers in an unique laminate construction. Through the coextrusion process multilayer thin-film to thick-sheet laminate constructions can be made having bond interfaces of the highest integrity. These laminates can subsequently be fed through other downstream lamination processes, greatly expanding the plastic material solutions Bixby can provide to our clients.

COEXTRUSION PROCESS

CAPABILITIES

- Three-layer coex laminates up to 36” wide

- Coex laminates can be extrusion laminated onto other substrates through Bixby extrusion process lines

TECHNICAL SPECIFICATIONS

- Gauge range: 0.001” to 0.100” (0.0254mm to 2.54mm)

RELATED MATERIALS

Bixby is experienced processing most every commercially available thermoplastic family. Additionally, we work with specialty, custom and developmental polymers and formulations, hot melts, and tie layers. These can be extruded as monolayer film and sheet or combined with other substrates for manufacture of custom laminations.

Contact Us

Have a question about our processes or capabilities? Do you need a plastic solution for your next project? Are you interested in learning more about Bixby’s custom manufacturing possibilities? Contact us and we will be happy to assist!